Design Standards:

Designed in accordance with EN12756 standard

"K" variant features reverse pressure design

"S" variant indicates special seal configuration

Common Material Combinations:

Sealing Faces: Graphite, Silicon Carbide, Tungsten Carbide

Secondary Seals: NBR, FKM, EPDM, FFKM

Metal Components: 304, 316, Hast.C, Duplex Steel, Titanium

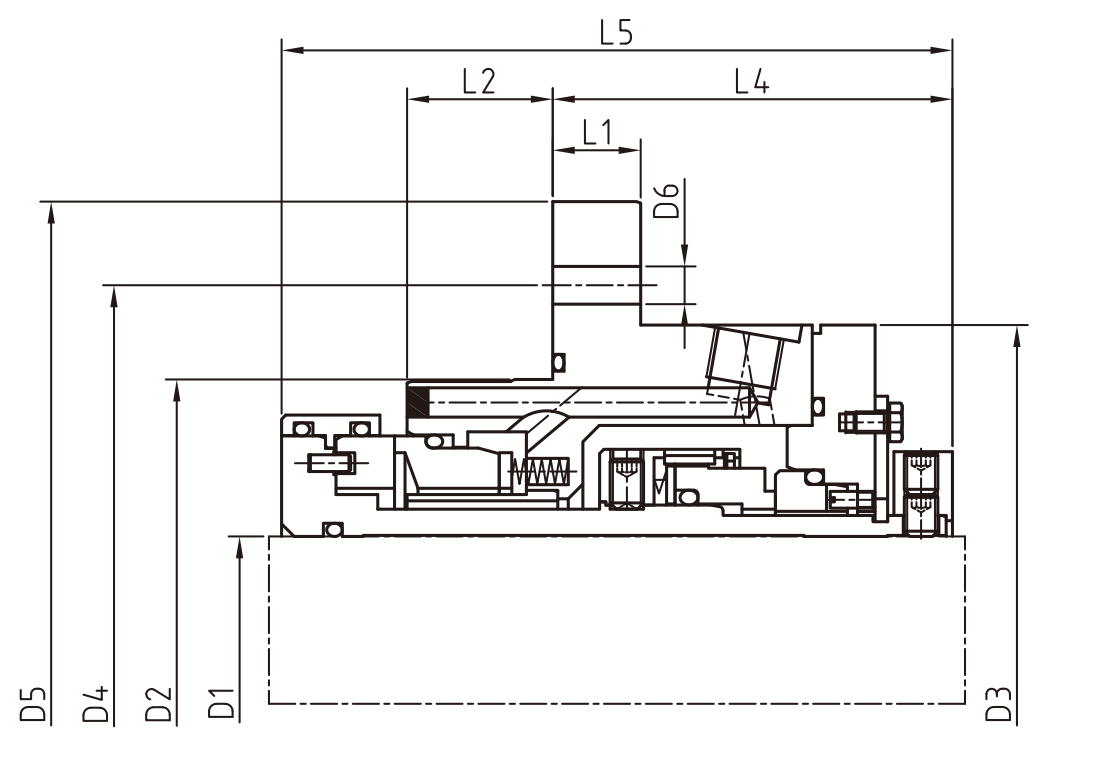

Structural Description:

Double cartridge mechanical seal, bi-directional balanced type, spring-protected design

Operating Parameters:

Temperature: -20°C to 180°C

Surface Speed: 23 m/s

Pressure: 25 bar (2.5MPa)

I. Scope of Application

Cartridge Seals for Chemical Process Pumps

Primarily used in various centrifugal pumps within the petroleum and fine chemical industries, including feed pumps, reflux pumps, and circulation pumps. This series of seals must meet the installation requirements of API 610 (or equivalent standards) for seal chambers. They are suitable for temperatures ranging from -40°C to 400°C and pressures from 0 to 4.0 MPa, capable of handling various fluids, including hydrocarbons, solvents, and acidic/alkaline media.

Cartridge Seals for Water and General Pumps

Suitable for applications such as water supply systems, air conditioning systems, and irrigation systems that transport clean water or similar clear liquids. These seals feature a compact structure and easy installation, with a maximum operating temperature of 220°C and a maximum surface speed of 20 m/s, meeting the requirements of most general-purpose pumps.

Cartridge Seals for High-Temperature Oil Pumps

Specifically designed for sealing oil-based media such as thermal oil, lubricating oil, and fuel oil. They are suitable for refineries, thermal power plants, ships, and other applications. Utilizing special sealing face materials and secondary seals, these seals can operate stably at temperatures up to 425°C.

II. Usage Methods

Pre-Installation Inspection

- Verify the fit dimensions between the sleeve and shaft, ensuring the clearance meets standard requirements.

- Check the seal chamber dimensions to ensure compatibility with the seal's external dimensions.

- Inspect all fasteners for integrity.

Installation Steps

- Slide the cartridge seal assembly onto the shaft end and push it to the installation position.

- Evenly tighten the gland bolts to the specified torque value.

- Remove the positioning shim or fixing device and check if the seal is in a floating state.

Pre-Operation Debugging

- Manually rotate the shaft 2–3 turns to confirm no sticking or obstruction.

- Jog the motor to verify the correct rotation direction.

- Operate at low speed for 30 minutes, observing leakage and temperature rise.

Routine Maintenance

- Check seal leakage daily and record data.

- Inspect vibration levels weekly.

- Monitor auxiliary system operation monthly.

- Examine seal wear every six months.

III. Common Issue Handling

Leakage After Installation

- First, check if the positioning device has been completely removed.

- Confirm that the sleeve surface is undamaged.

- Inspect the sealing faces for contamination.

Overheating During Operation

This may be due to excessive face pressure or inadequate lubrication.

- Verify that the spring compression is appropriate.

- Ensure the flushing system is functioning properly.

- Adjust the face pressure if necessary.

Short Service Life

- Focus on checking if the medium contains impurities.

- Confirm the seal selection is correct for the application.

- Inspect equipment for excessive vibration.

- Verify if operating conditions have changed.

IV. Precautions

Storage Requirements

- Seals should be stored in a dry, dust-free environment, avoiding direct sunlight.

- If stored for more than 6 months, re-inspection is required.

Installation Environment

- The installation site should be kept clean, avoiding work in dusty environments.

- Thoroughly clean the seal chamber before installation.

Operational Guidelines

- Dry running without media is strictly prohibited.

- Ensure the seal chamber is filled with media before startup.

- When shutting down, stop the equipment before stopping the auxiliary system.

V. Technical Support Services

The company has established a customer after-sales emergency response mechanism. Always refer to the installation and maintenance manual of the corresponding model for specific operations. If technical support is required for special working conditions, please contact our engineering team promptly.

Copyright © Jiangsu GOLDEN EAGLE Fluid Machinery Co., Ltd. - Privacy Policy