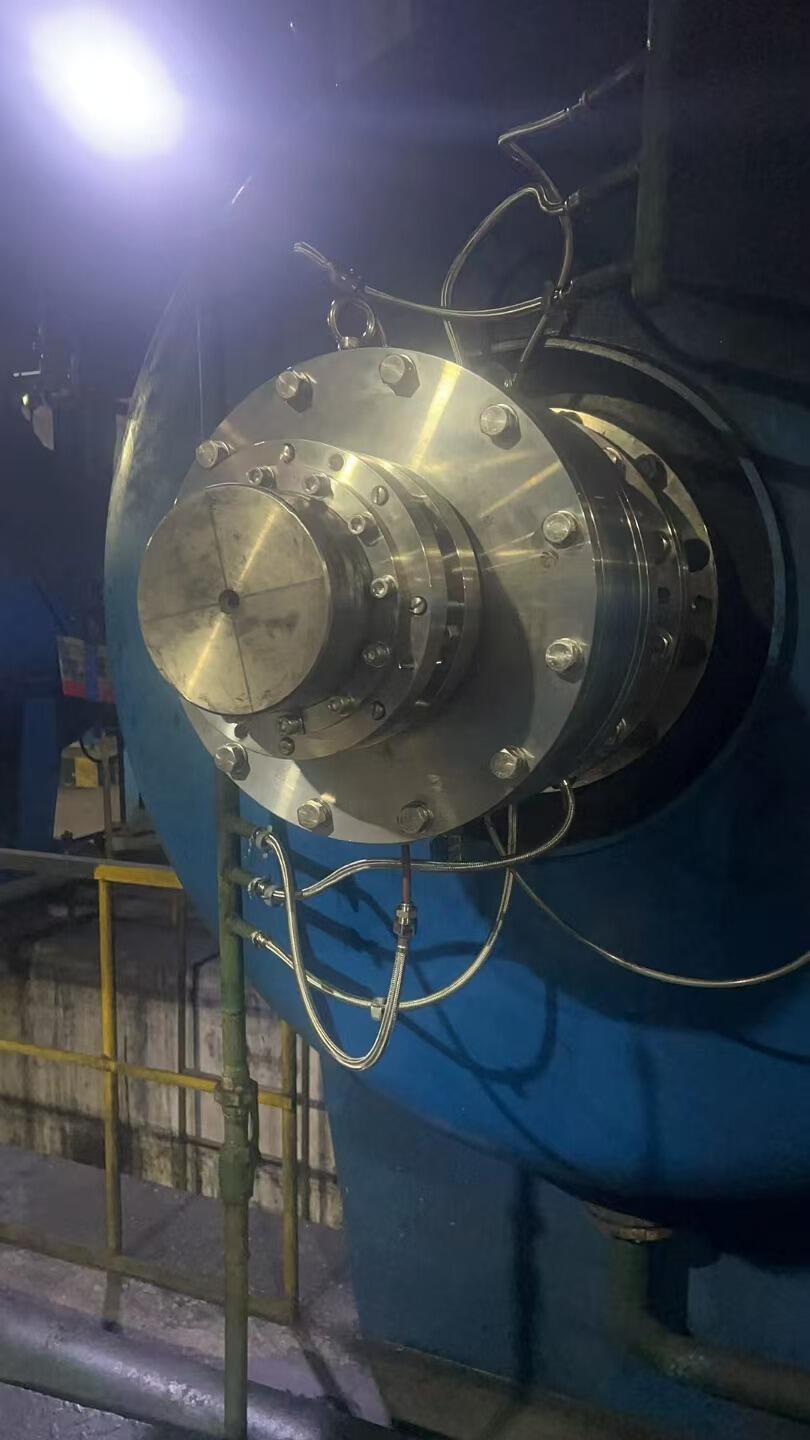

Jiangsu Golden Eagle Ultra-High Temperature (650°C) Horizontal Reactor Mechanical Seal—On-Site Installation & Commissioning

Jiangsu Golden Eagle Ultra-High Temperature (650°C) Horizontal Reactor Mechanical Seal—On-Site Installation & Commissioning

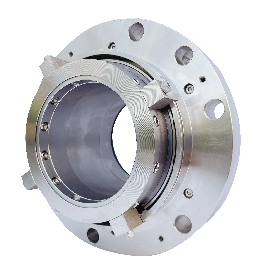

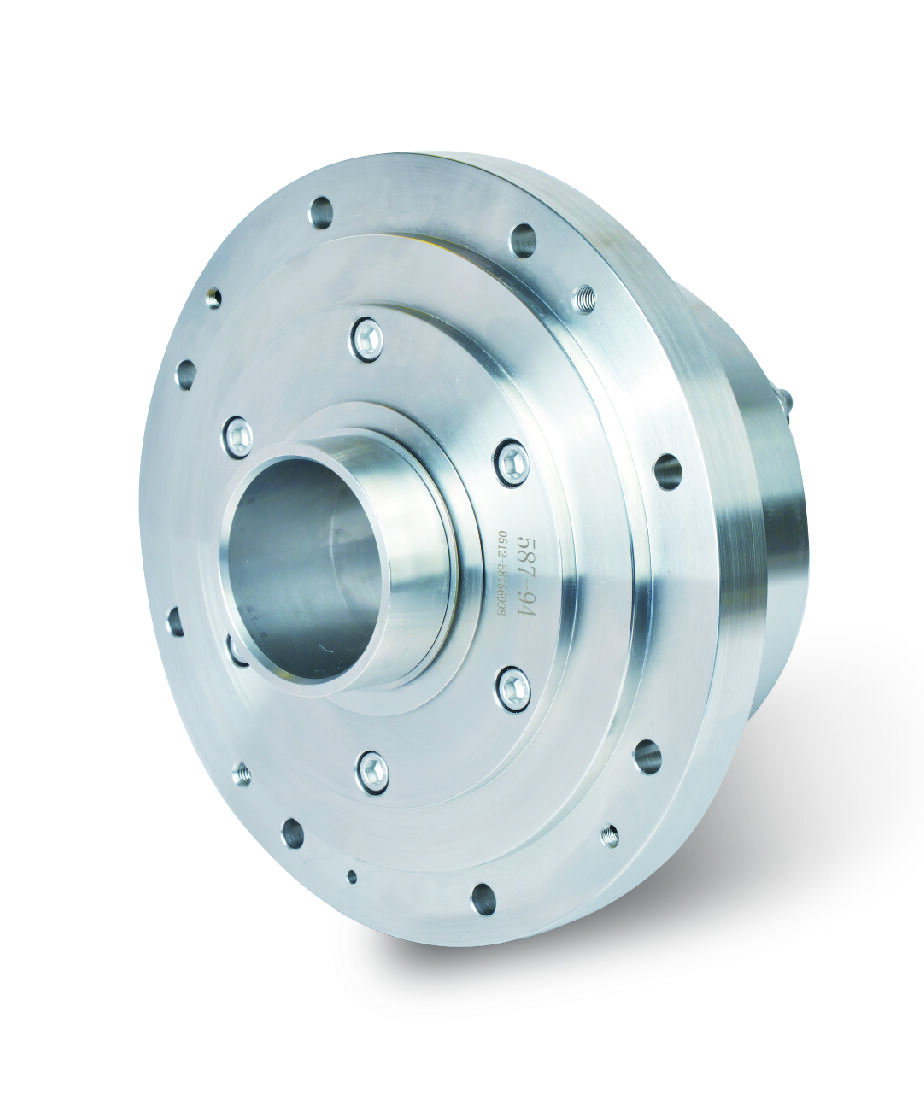

This series of images documents the on-site installation and commissioning process of Jiangsu Golden Eagle's mechanical seal, specifically designed for ultra-high temperature (650°C) horizontal reactors. Engineered for extreme temperature and operational conditions, the seal is deployed in hot and cold reactor equipment within lithium battery cathode and anode material production facilities.

Key Features:

1. Ultra-High Temperature Resistance: Maintains structural integrity and reliable sealing performance at continuous operating temperatures up to 650°C.

2. Compensation for Horizontal Reactor Shaft Expansion: Features a unique bellows compensation structure designed to accommodate the thermal expansion and contraction of the mixer shaft in horizontal reactors during high-low temperature cycles, ensuring uninterrupted sealing performance.

3. Advanced Material Technology: Utilizes specialized materials and high-temperature-resistant components to prevent deformation and performance degradation.

4. On-Site Technical Guidance: Golden Eagle engineers provide end-to-end professional support from installation and commissioning to operational validation.