The G51S series slurry media mechanical seal is typically installed vertically and is primarily used in the paper industry equipment, though it is also suitable for other industrial applications.

Common Material Combinations

Sealing Faces: Silicon Carbide, Tungsten Carbide

Secondary Seals: NBR, FKM, EPDM, FFKM

Metal Components: 304, 316, Hast.C, Duplex Steel, Titanium

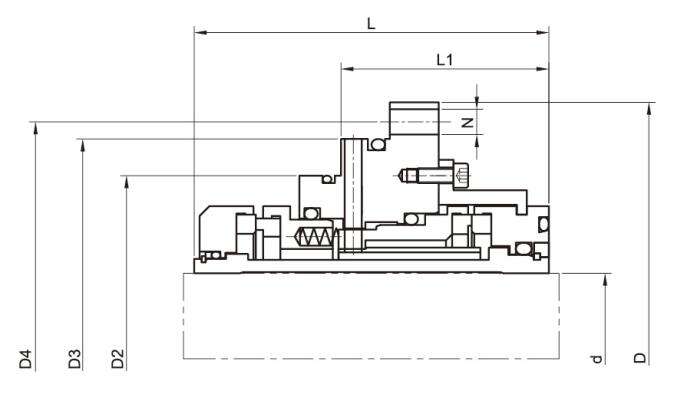

Structural Description

Double cartridge mechanical seal, balanced type

Operating Parameters

Temperature: -20°C to 220°C

Surface Speed: 23 m/s

Pressure: 25 bar (2.5MPa)

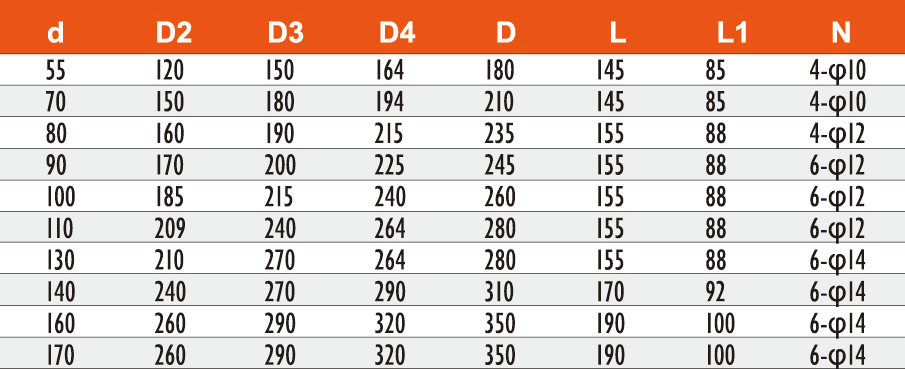

Standard Shaft Sizes: 55–170 mm

Metric dimensions (mm), with sizes above 170mm available for customization.

I. Scope of Application

Heavy-Duty Slurry Pump Seals

Primarily suitable for conveying high-concentration, highly abrasive media. Typical applications include mine tailings transportation, coal washing processes, and metallurgical slurry processing. This type of seal utilizes hard-face material combinations and can handle highly abrasive media with solid particle concentrations up to 60% and particle sizes up to 6 mm. Maximum operating pressure reaches 2.5 MPa.

Chemical Slurry Seals

Specifically designed for handling corrosive crystalline media, mainly used in process pumps for phosphorous chemical, salt chemical, and titanium dioxide production industries. This seal system employs special material combinations and flushing schemes, providing both corrosion resistance and effective prevention of crystalline clogging. Operating temperature range: -20°C to 120°C.

Wastewater Treatment Seals

Suitable for equipment such as sludge pumps and grit chamber agitators in municipal wastewater treatment plants, effectively handling media containing fibers, sand particles, and other foreign matter. This seal features large-passage flushing systems and anti-clogging structures, capable of passing solid particles up to 5 mm.

II. Usage Methods

Pre-Installation Inspection

- Verify sleeve wear condition; radial runout should not exceed 0.3 mm.

- Check seal chamber passages for unobstructed flow; remove any residual debris.

- Confirm cooling system pipeline畅通性.

Proper Installation Steps

- Install wear-resistant sleeves and main seal components in sequence.

- Evenly tighten gland bolts to ensure consistent clearance around the perimeter.

- Connect flushing water pipelines and confirm correct flow direction.

Operating Parameter Adjustment

- Adjust flushing water flow according to medium concentration; increase flow by 30% for high-concentration conditions.

- Adjust seal face specific pressure based on particle hardness; reduce spring pressure appropriately for highly abrasive media.

Routine Maintenance Procedures

- Check flushing water pressure each shift, ensuring it exceeds seal chamber pressure by 0.1-0.2 MPa.

- Record seal leakage daily.

- Clean filter screens weekly.

- Measure seal ring wear monthly.

III. Common Issue Handling

Rapid Seal Face Wear

- First, check if flushing water contains impurities and confirm filter normal operation.

- Next, verify if medium concentration exceeds design range.

- Finally, confirm suitability of seal face material selection.

Flushing Pipeline Clogging

- Immediately switch to standby filter; disassemble and clean clogged filter screen.

- Check flushing water source quality; add pre-filtration device if necessary.

Abnormal Vibration and Noise

- May be caused by impeller wear-induced imbalance or bearing damage.

- Shut down to inspect impeller condition.

- Check bearing clearance.

- Simultaneously inspect seal components for integrity.

IV. Precautions

Material Selection Guidelines

- Use silicon carbide vs. silicon carbide friction pairs for strong acid media.

- Select tungsten carbide materials for high-hardness particle conditions.

- Avoid stainless steel components for media containing chloride ions.

Flushing System Requirements

- Must use clean flushing water with solid content not exceeding 50 mg/L.

- Maintain stable flushing water pressure with fluctuations within ±5%.

- Implement pipeline freeze protection measures in winter.

Safety Operation Procedures

- Thoroughly flush seal chamber before maintenance.

- Wear protective equipment when replacing seals.

- Never adjust seal gland during operation.

V. Technical Support Services

The company has established a customer after-sales emergency response mechanism. Always refer to the installation and maintenance manual for the specific model during operation. Contact our engineering team promptly for technical support in special working conditions.

Copyright © Jiangsu GOLDEN EAGLE Fluid Machinery Co., Ltd. - Privacy Policy