The G10/11 series welded metal bellows mechanical seal operates without dynamic secondary seals, eliminating the risk of seal failure caused by relative sliding against the shaft. When the bellows serves as the rotating element, centrifugal force during rotation enables a self-cleaning function.

Common Material Combinations:

Sealing Faces: Graphite, Silicon Carbide, Tungsten Carbide

Secondary Seals: NBR, FKM, EPDM, FFKM, Flexible Graphite

Metal Components: 304, 316, Hast.C, Duplex Steel, Titanium, 4J42

Bellows: 316, AM350, C-276, Alloy 718, Titanium

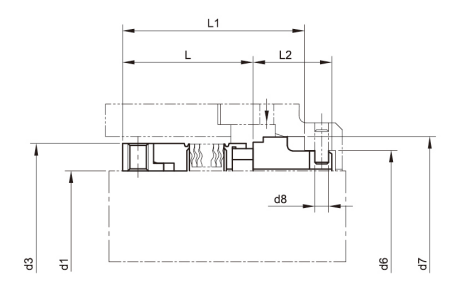

Structural Description:

Single mechanical seal, balanced type, bellows design

Operating Parameters:

Temperature: -50°C to 204°C

Surface Speed: 23 m/s

Pressure: 27 bar (2.7MPa)

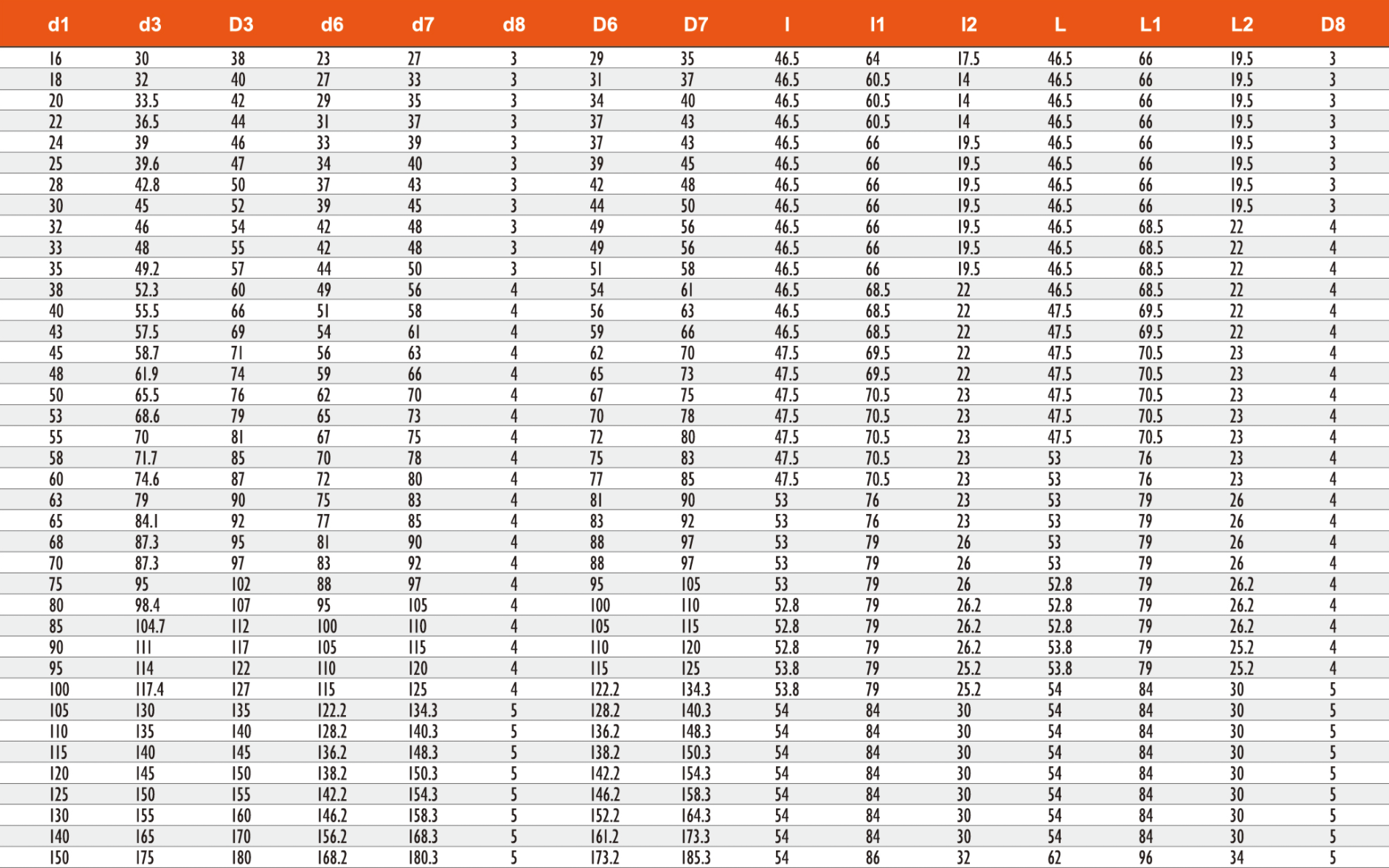

Metric dimensions (mm), with sizes above 150mm available for customization.

I. Scope of Application

Bellows Seals for High-Temperature Applications

Primarily suitable for sealing high-temperature media above 176°C, with typical applications including hot oil pumps, molten salt pumps, and high-temperature reactors. This type of seal features a multi-layer metal bellows structure, capable of withstanding continuous operating temperatures up to 450°C, making it particularly suitable for conditions with severe temperature fluctuations.

Bellows Seals for Highly Corrosive Media

Designed specifically for handling strong acids, alkalis, and other corrosive media, these seals are widely used in specialty pumps within the chemical, pharmaceutical, and electroplating industries. Utilizing corrosion-resistant metal bellows materials such as Hastelloy and titanium, they can withstand corrosive media with pH values ranging from 1 to 14.

Bellows Seals for High-Speed Equipment

Suitable for high-speed pumps, compressors, and turbo machinery with rotational speeds exceeding 5,000 rpm. These seals incorporate a dynamic balance design, achieving maximum surface speeds of up to 100 m/s while maintaining stable sealing performance under high-speed conditions.

Bellows Seals for Crystallization-Prone Media

Designed for media prone to crystallization or solidification, these seals are commonly used in industries such as salt production, alkali manufacturing, and fertilizers. The unique bellows structure prevents seal failure caused by media crystallization, ensuring long-term stable operation under crystallization-prone conditions.

II. Usage Methods

Pre-Installation Inspection

- Ensure the radial runout of the shaft or sleeve does not exceed 0.05 mm.

- Check the seal chamber dimensions and surface finish.

- Verify that the bellows are free from mechanical damage or deformation.

Correct Installation Steps

- Use specialized installation tools to push the seal into the working position.

- Tighten the gland bolts evenly to ensure the seal faces are perpendicular to the shaft axis.

- After installation, manually rotate the shaft to confirm no interference.

Operating Parameter Settings

- Set an appropriate preheating program based on the medium temperature.

- Gradually increase the pressure to the working level while observing leakage conditions.

- Continuously monitor sealing performance after reaching normal operating conditions.

Routine Maintenance Procedures

- Record seal operating temperature and leakage daily.

- Inspect the bellows for signs of fatigue weekly.

- Check seal face wear monthly.

- Perform comprehensive performance testing quarterly.

III. Common Issue Handling

Bellows Rupture

- Immediately shut down the equipment and check whether the medium temperature exceeds the limit.

- Confirm whether frequent drastic temperature changes have occurred.

- Inspect whether the bellows material is suitable for the operating media.

Abnormal Seal Face Wear

- This may be due to solid particles in the medium or inadequate lubrication.

- Check the filtration system for proper operation.

- Ensure the flushing system is functioning effectively.

- Replace with more wear-resistant seal face materials if necessary.

Gradual Performance Degradation

- Focus on checking whether the bellows show signs of fatigue.

- Verify whether the spring compensation capability is sufficient.

- Inspect the seal faces for thermal deformation.

IV. Precautions

Key Material Selection Points

- For high-temperature applications, prioritize AM350 material.

- For highly corrosive media, use Hastelloy.

- For media containing chloride ions, use titanium.

- For high-speed applications, choose Inconel 718.

Operational Limitations

- Do not exceed the maximum design temperature during operation.

- Avoid abrupt temperature changes.

- Operation without media is strictly prohibited.

- Ensure sufficient preheating before startup.

Safety Precautions

- Install thermal insulation protection for high-temperature applications.

- Equip with leakage detection devices when handling toxic media.

- Regularly inspect the bellows for fatigue.

V. Technical Support Services

The company has established a customer after-sales emergency response mechanism. Always refer to the installation and maintenance manual of the corresponding model for specific operations. If technical support is required for special working conditions, please contact our engineering team promptly.

Copyright © Jiangsu GOLDEN EAGLE Fluid Machinery Co., Ltd. - Privacy Policy