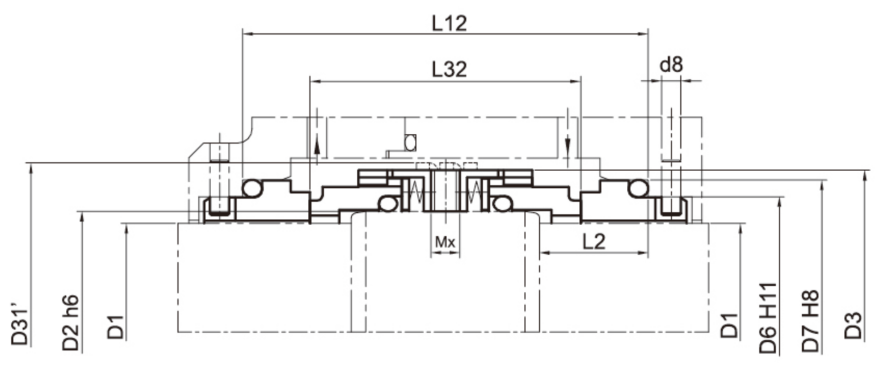

The 60 Series non-cartridge mechanical seal is designed in compliance with EN12756 and GB/T 6556 standards, offering strong interchangeability. The stationary ring installation dimensions conform to the G9 and G16 specifications under EN12756, and the stationary ring may be secured using a circlip. The "F" variant incorporates a pumping spiral design and requires attention to rotation direction.

Common Material Combinations:

Sealing Faces: Graphite, Silicon Carbide, Tungsten Carbide

Secondary Seals: NBR, FKM, EPDM, FFKM

Metal Components: 304, 316, Hast.C, Duplex Steel, Titanium

Structural Description:

The 60BD(F) is a double mechanical seal, balanced type. While maintaining identical installation dimensions, the 60BD(F) may utilize a wave spring. The "F" version with pumping spiral requires specification of rotation direction.

Operating Parameters:

Temperature: -50 °C to 204 °C

Surface Speed: 23 m/s

Pressure: 32bar(3.2MPa)

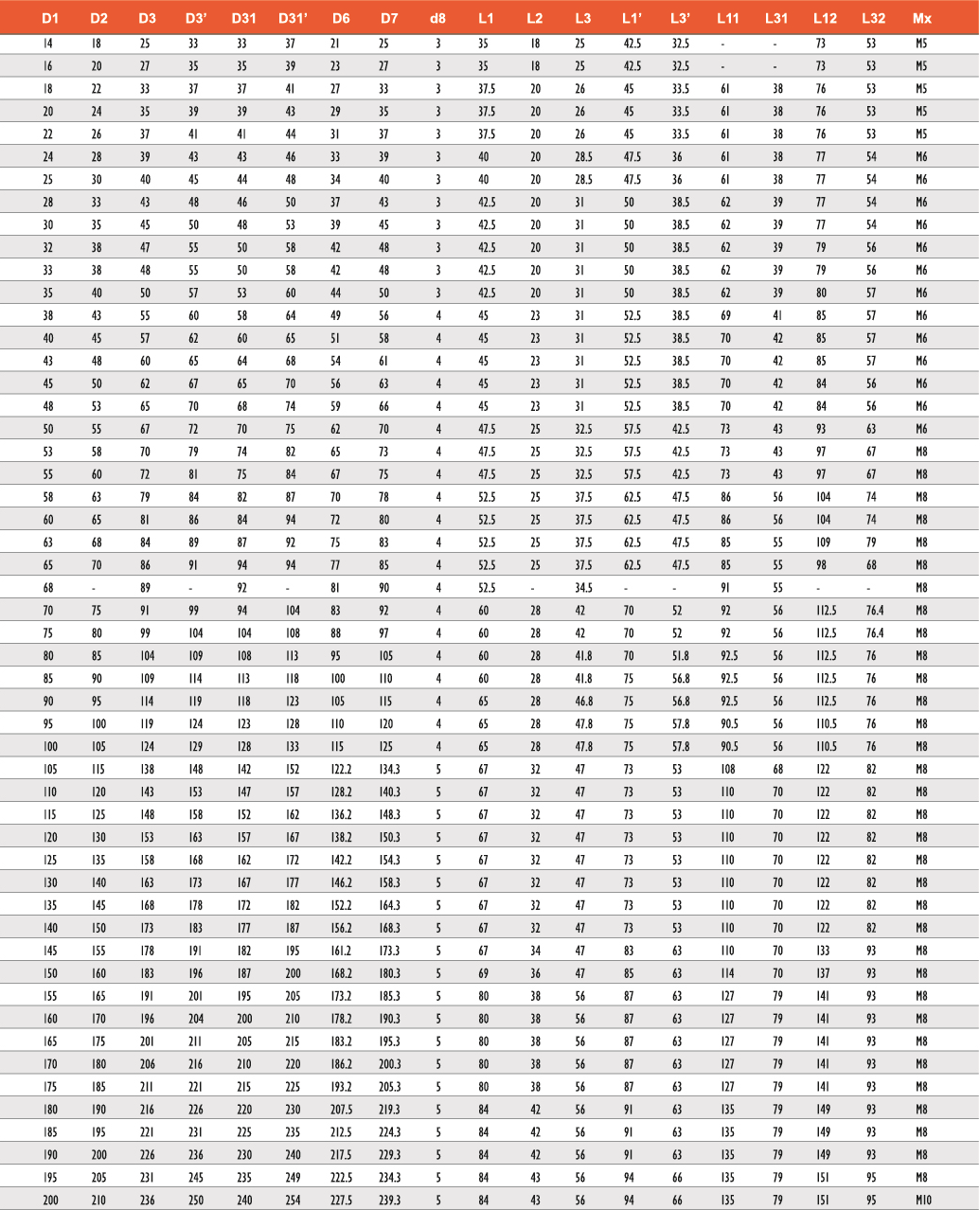

Standard Shaft Sizes: 14–200 mm (custom sizes above 200 mm available)

Metric dimensions (mm), with sizes above 200mm available for customization.

I. Scope of Application

Standard Seals for Water and Non-Corrosive Media

Mainly used in various centrifugal pumps transporting neutral media such as clean water, cooling water, and lubricating oil. These seals employ cost-effective material combinations and are suitable for conventional operating conditions with temperatures ranging from -20°C to 100°C and pressures not exceeding 1.0 MPa. They are widely used in water supply systems, air conditioning circulation, fire pumps, and other applications.

Standard Seals for General Chemical Media

Suitable for chemical process pumps handling weak acids, weak alkalis, and other general chemical media. Utilizing corrosion-resistant material combinations, these seals can handle chemical media with a pH range of 4–10 and operate within a temperature range of -20°C to 120°C, meeting the sealing requirements of most chemical production facilities.

Standard Seals for Oil-Based Media

Specifically designed for sealing various petroleum products such as lubricating oil, fuel oil, and hydraulic oil. These seals use oil-resistant materials and are suitable for oil-based applications with temperatures ranging from -30°C to 140°C. They are widely used in refineries, power plants, mechanical equipment, and other fields.

Food and Pharmaceutical Grade Standard Seals

Designed in accordance with sanitary standards, these seals are suitable for pump equipment in the food, pharmaceutical, and beverage industries. They utilize FDA-certified materials, feature a dead-zone-free structural design, and can be fully disassembled for cleaning, meeting GMP specifications.

II. Usage Methods

Pre-Installation Preparation

- Check the radial runout of the shaft or sleeve, ensuring it does not exceed 0.05 mm.

- Clean the shaft surface and seal chamber to ensure no burrs or impurities remain.

- Verify that the spring compression dimensions meet technical requirements.

Correct Installation Procedure

- Install the seal components in sequence, ensuring correct orientation.

- Tighten the gland bolts evenly to ensure the sealing faces remain parallel.

- After installation, manually rotate the shaft to confirm smooth operation without sticking.

Operation and Debugging

- Jog the equipment to verify the correct rotation direction.

- Operate at low speed for 30 minutes to observe leakage conditions.

- Gradually increase pressure to the working level and check sealing performance.

Routine Maintenance

- Check seal leakage daily.

- Inspect vibration and temperature rise weekly.

- Examine seal wear monthly.

- Perform comprehensive inspection and maintenance quarterly.

III. Common Issue Handling

Excessive Initial Leakage

- First, check the cleanliness of the sealing faces and ensure they are undamaged.

- Next, verify that the spring compression is correct.

- Finally, confirm that the secondary seals are properly installed.

Sudden Leakage During Operation

This may be due to contaminants entering the sealing faces or sudden changes in operating conditions.

- Immediately inspect the filtration system.

- Confirm whether media parameters have changed.

- If necessary, shut down for maintenance.

Short Seal Lifespan

- Focus on checking whether equipment vibration exceeds standards.

- Confirm whether the media contains abrasive particles.

- Verify whether the seal selection is suitable for the operating conditions.

IV. Precautions

Key Points for Selection

- Choose appropriate seal materials based on media characteristics.

- Determine the seal structure according to working pressure.

- Select the seal specifications based on shaft diameter and rotational speed.

Operational Restrictions

- Dry running is strictly prohibited.

- Avoid abrupt changes in operating conditions.

- Do not exceed the design pressure during operation.

- Ensure the pump cavity is filled with media before startup.

Maintenance Requirements

- Use genuine spare parts for replacements.

- Perform maintenance according to the specified cycles.

- Maintain a seal operation record.

V. Technical Support Services

The company has established a customer after-sales emergency response mechanism. Always refer to the installation and maintenance manual of the corresponding model for specific operations. If technical support is required for special working conditions, please contact our engineering team promptly.

Copyright © Jiangsu GOLDEN EAGLE Fluid Machinery Co., Ltd. - Privacy Policy