Agitators are primarily constructed from stainless steel or enamel materials. Our mechanical seals offer various designs—including single seal, double seal, with bearing, and without bearing—to accommodate different working conditions. Specialized designs can mitigate limitations related to diameter, pressure, surface speed, temperature, and axial displacement.

Common Material Combinations

Sealing Faces: Graphite, Silicon Carbide, Tungsten Carbide

Secondary Seals: FEP-encapsulated, FKM, EPDM, FFKM

Metal Components: 304, 316, Hast.C, Duplex Steel, Titanium

Bellows: 316, AM350, Hast.C, Alloy 718, Titanium

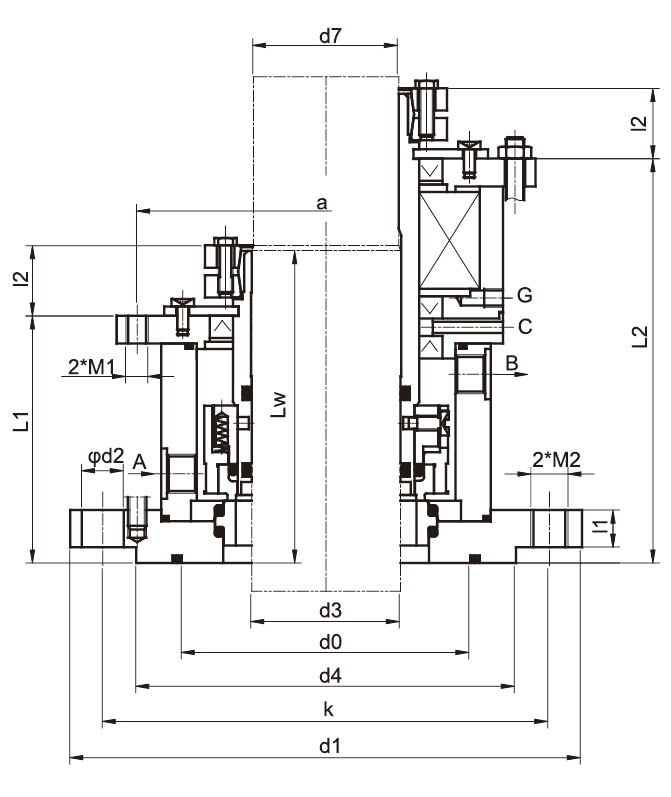

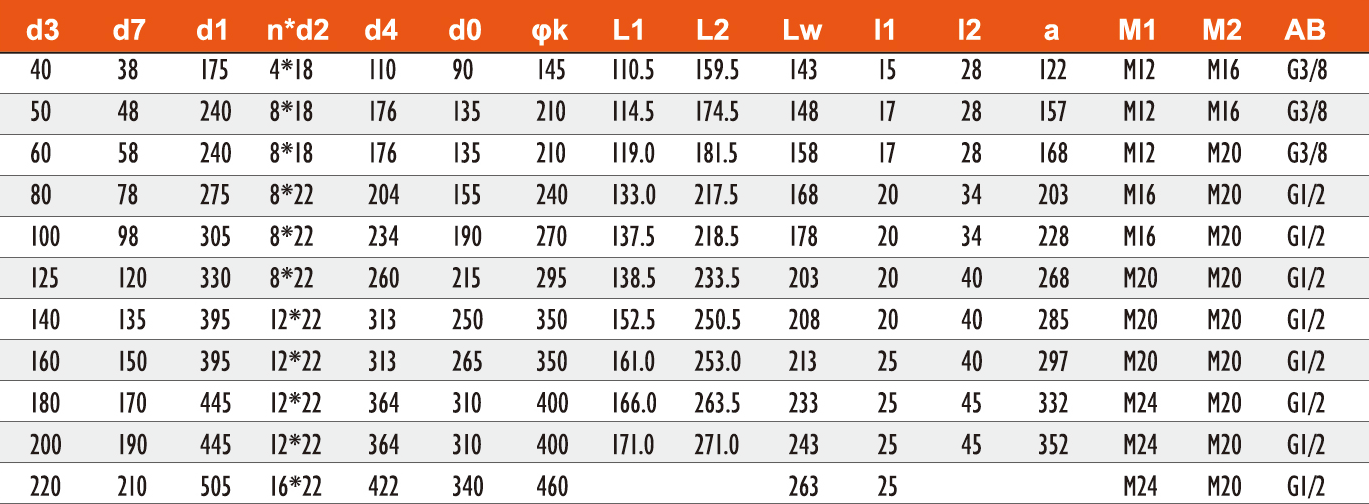

Structural Description

Single cartridge mechanical seal, unbalanced type, anti-vacuum design; "Z" variant includes bearing support.

Operating Parameters

Temperature: -20°C to 220°C

Surface Speed: 5 m/s

Pressure: 13 bar (1.3MPa)

Metric dimensions (mm), with sizes above 220mm available for customization.

I. Scope of Application

Top-Entry Agitator Seals

Primarily suitable for shaft sealing in various reaction kettles and mixing tanks. Typical applications include polymerization reactions in chemical production, mixing and preparation in the pharmaceutical industry, and blending in the food industry. This type of seal must accommodate the inherent deflection and vibration of the agitator shaft and is suitable for working pressures not exceeding 2.5 MPa.

Side-Entry Agitator Seals

Specifically designed for agitators installed on the side of equipment, mainly used in large storage tanks for material mixing and suspension stirring. This seal system employs a special structural design to withstand combined axial and radial loads, making it suitable for high-viscosity media environments.

Bottom-Entry Agitator Seals

Suitable for applications requiring agitation from the bottom of the equipment, commonly found in crystallizers and settling tanks. This type of seal considers the effects of medium static pressure and solid particles, featuring an anti-particle accumulation structure.

II. Usage Methods

Installation Preparation

- Check the radial runout of the agitator shaft, ensuring it does not exceed 0.5 mm.

- Confirm that the shaft surface is free from wear, corrosion, or other defects.

- Verify that the seal chamber dimensions meet design requirements and clean the inner wall to ensure no impurities remain.

Installation Positioning

- For top-entry seals, ensure the perpendicularity deviation between the seal face and the shaft does not exceed 0.1 mm.

- For side-entry seals, precisely adjust the angle between the seal and the shaft, controlling the deviation within 0.5 degrees.

Operating Parameter Settings

- Set the seal flushing plan according to medium characteristics; increase flushing flow for high-viscosity media.

- Adjust spring compression based on agitator speed; reduce spring-specific pressure appropriately for high-speed conditions.

Routine Maintenance

- Check seal leakage daily and record changes in leakage volume.

- Inspect auxiliary system operating parameters weekly, including flushing pressure and flow rate.

- Examine seal wear monthly and measure the thickness of the seal rings.

III. Common Issue Handling

Abnormal Seal Face Wear

- First, check if the radial runout of the agitator shaft exceeds the standard.

- Then, inspect the medium for abrasive particles.

- Finally, verify whether the spring compression is appropriate.

- If wear is severe, recalibrate the agitator shaft and replace the seal components.

Excessive Seal Leakage

- This may be due to seal face deformation, aging of secondary seals, or sleeve wear.

- Start by checking the flatness of the seal faces.

- Then, inspect the elasticity of the O-rings.

- Replace all seal components if necessary.

Abnormal Seal Temperature Rise

- Check whether the flushing system is unobstructed and ensure the cooling water supply is normal.

- Inspect whether high medium viscosity is causing increased frictional heat.

- Confirm that the seal face specific pressure is within the allowable range.

IV. Precautions

Equipment Alignment Requirements

- During installation, ensure the concentricity between the agitator shaft and the seal chamber, with a maximum allowable deviation of 0.2 mm.

- Pay special attention to vibration during the initial operation of the equipment and make immediate adjustments if abnormalities are detected.

Medium Adaptability

- For crystallization-prone media, use seal structures with large spring designs.

- For media containing solid particles, configure an effective flushing system.

- For corrosive media, select appropriate material combinations.

Safety Operation Standards

- Adjusting the seal gland bolts during equipment operation is strictly prohibited.

- During maintenance, depressurize and cool down first to ensure the equipment is in a safe state.

- Use specialized tools when replacing seals to avoid damaging the seal faces.

V. Technical Support Services

The company has established a customer after-sales emergency response mechanism. Always refer to the installation and maintenance manual of the corresponding model for specific operations. If technical support is required for special working conditions, please contact our engineering team promptly.

Copyright © Jiangsu GOLDEN EAGLE Fluid Machinery Co., Ltd. - Privacy Policy